What is the difference between an acid-etched zinc plaque and a bronze casting plaque?

You can order either a zinc or a bronze casting plaque from Pella Engraving Company.

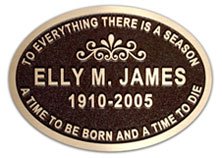

A bronze casting plaque is created with a poured mold process and the font size must be at least 1/4″ tall. The raised areas on a bronze plaque are the natural bronze color of the metal and cannot be colored silver. Usually the bronze plaque is concave, 1/4″ thick in the center and 1/2″ thick at the edges. It is also available in 1/8″ thickness. Incorporated into the mold is a concealed stud area where threaded rods can be used for installation.

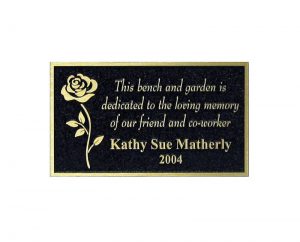

A zinc plaque is created with an acid-etched bath process, which allows for much smaller font size and more graphic details. The raised area on a zinc plaque is naturally silver, but can be given a gold or copper-tinted clear coat. This type of plaque is available in two thicknesses—0.064″ or 0.125″. The holes and screws mounting option is available for both thicknesses, and blind-mounted studs are available on the 0.125″ thickness.

At a glance, here are some of the differences between the two types of plaques:

- Cost – Typically a zinc plaque is less expensive than a bronze casting plaque.

- Font and design – Due to the zinc acid-etched process, a greater range of font sizes and more detailed graphics can be etched into a zinc plaque than a bronze casting plaque.

- Installation hardware – Zinc plaques can have holes and screws or blind-mount studs welded onto the back. Bronze castings typically have concealed studs poured into the mold.

- Color – The raised areas on zinc can be gold, silver, or copper colored. Bronze castings can only have a natural bronze color on the raised areas.

- Turnaround time – Zinc plaques are guaranteed to ship in 10 working days and bronze castings in 21 working days.

Zinc plaques—great for detail, quick turnaround, and outdoor durability.

A bronze casting plaque—a classic option.

The concealed stud area for

installation on a bronze casting plaque.

How many colors can be used on a magnesium or zinc plaque?

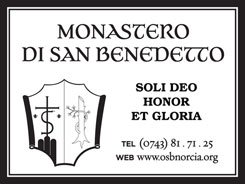

Many customers want multicolored plaques, often to duplicate a graphic logo or artwork. We have two options for painting plaques. Because magnesium and zinc are two-level plaques, we can paint-fill the recessed areas or tip (roll over with ink) the raised areas.

Recessed areas can be filled with one of our stock paint colors, or we can match as close as possible a PMS Pantone color number provided by the customer. Raised areas can be tipped with a limited number of primary colors.

Artwork provided for a plaque will have to be worked—we create raised lines that will hold the paint in place and keep it from mixing.

To summarize, the color options for magnesium or zinc plaques are unlimited!

Original artwork used to create the plaque to the right.

The recessed areas of the logo on this plaque were filled to match the colors desired by the customer.