Almost 20 years ago, Pella Engraving Company saw the potential in Metalphoto and invested in the equipment to put this highly innovative technology to work for its customers.

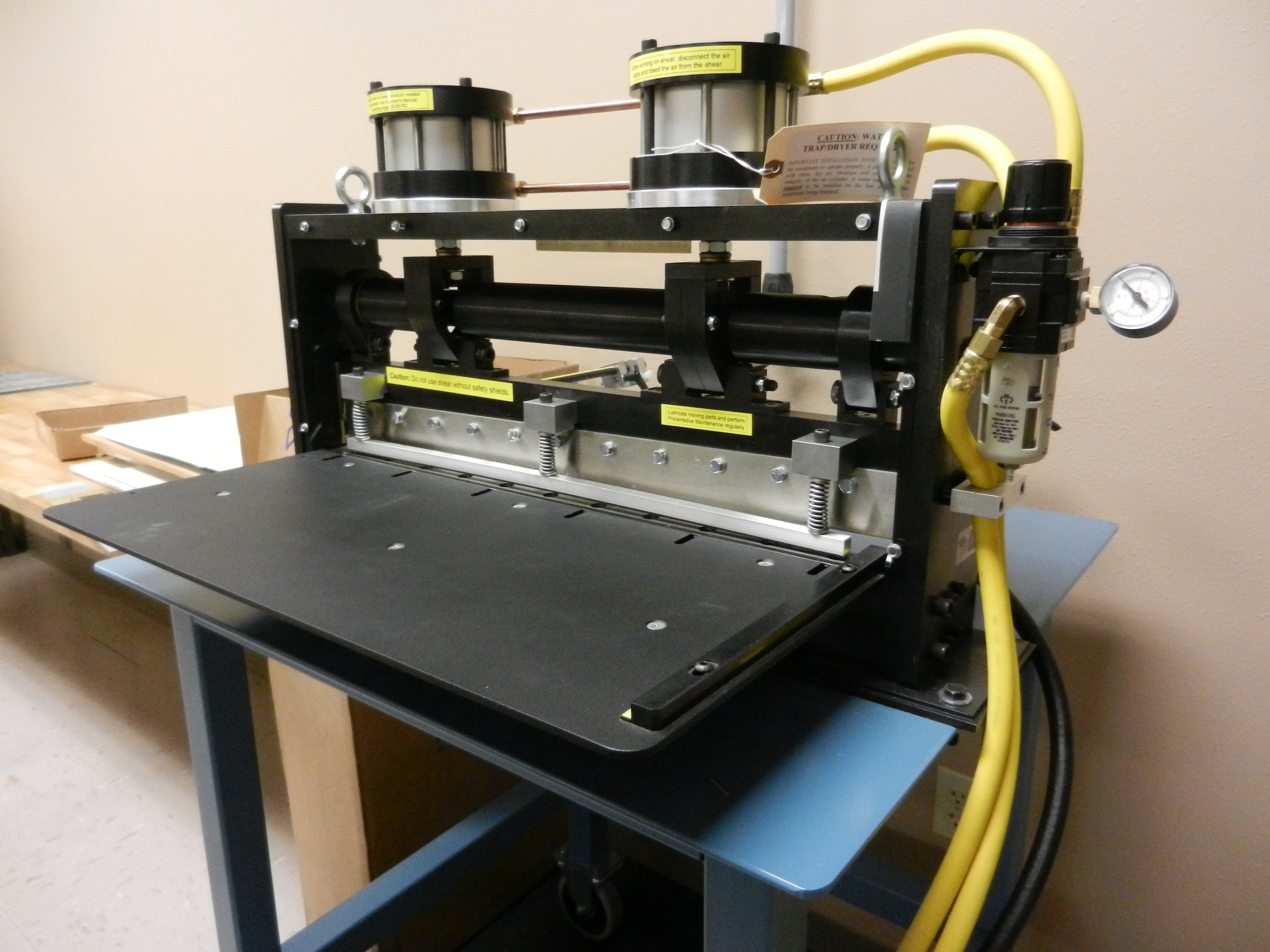

A unique process with many applications, Metalphoto requires an array of machines: developer tanks, sealing tanks, nippers, shears, and hole punchers. In recent years, demand for Metalphoto products like asset and ID tags has increased. In response, the PEC team improved its Metalphoto setup.

“We have the experience and capability to handle very large orders,” said Co-Owner Cory Vande Kieft. “With the updated workflow and the new tools we’ve integrated, our team is processing these orders even more efficiently.”

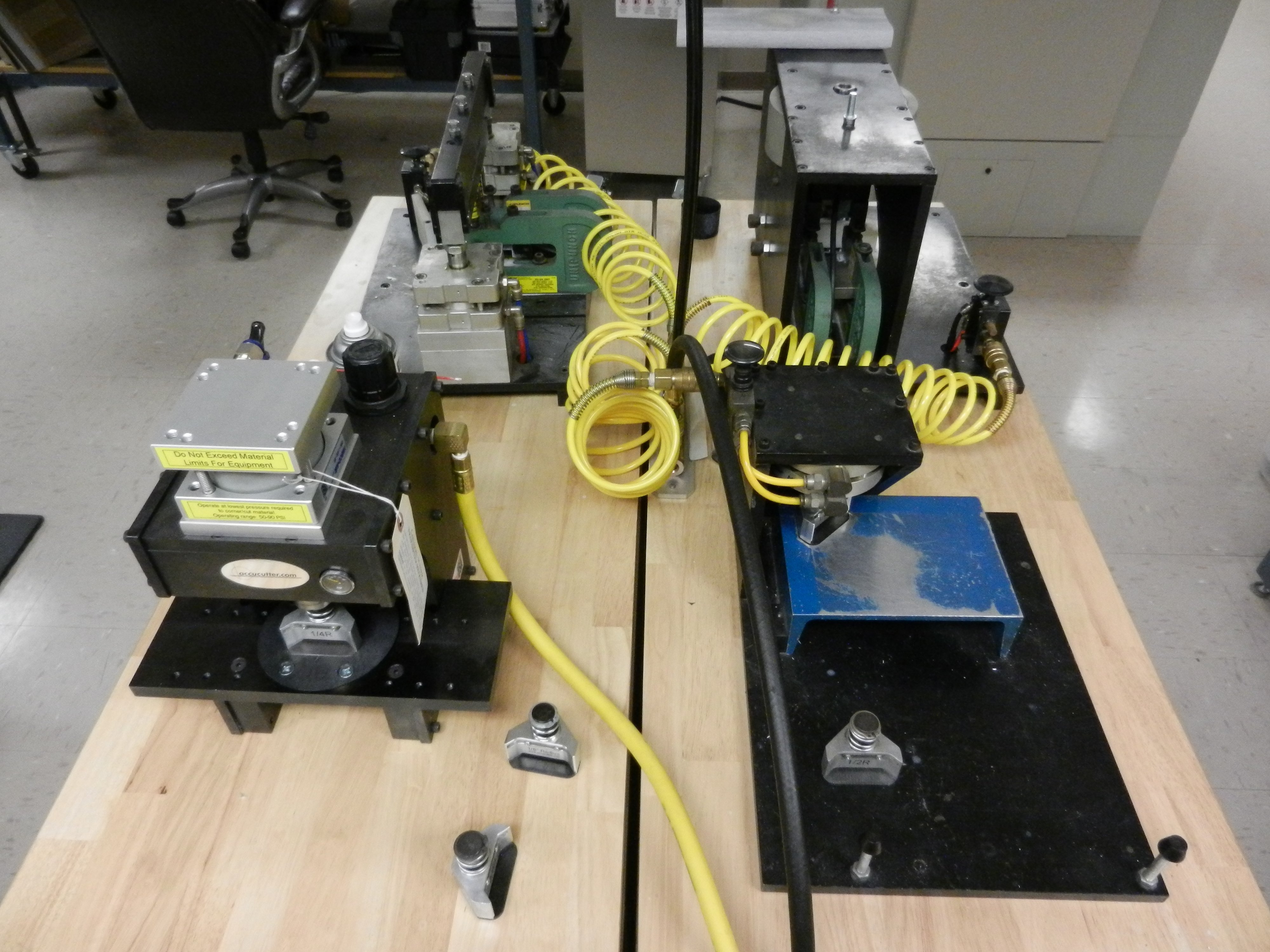

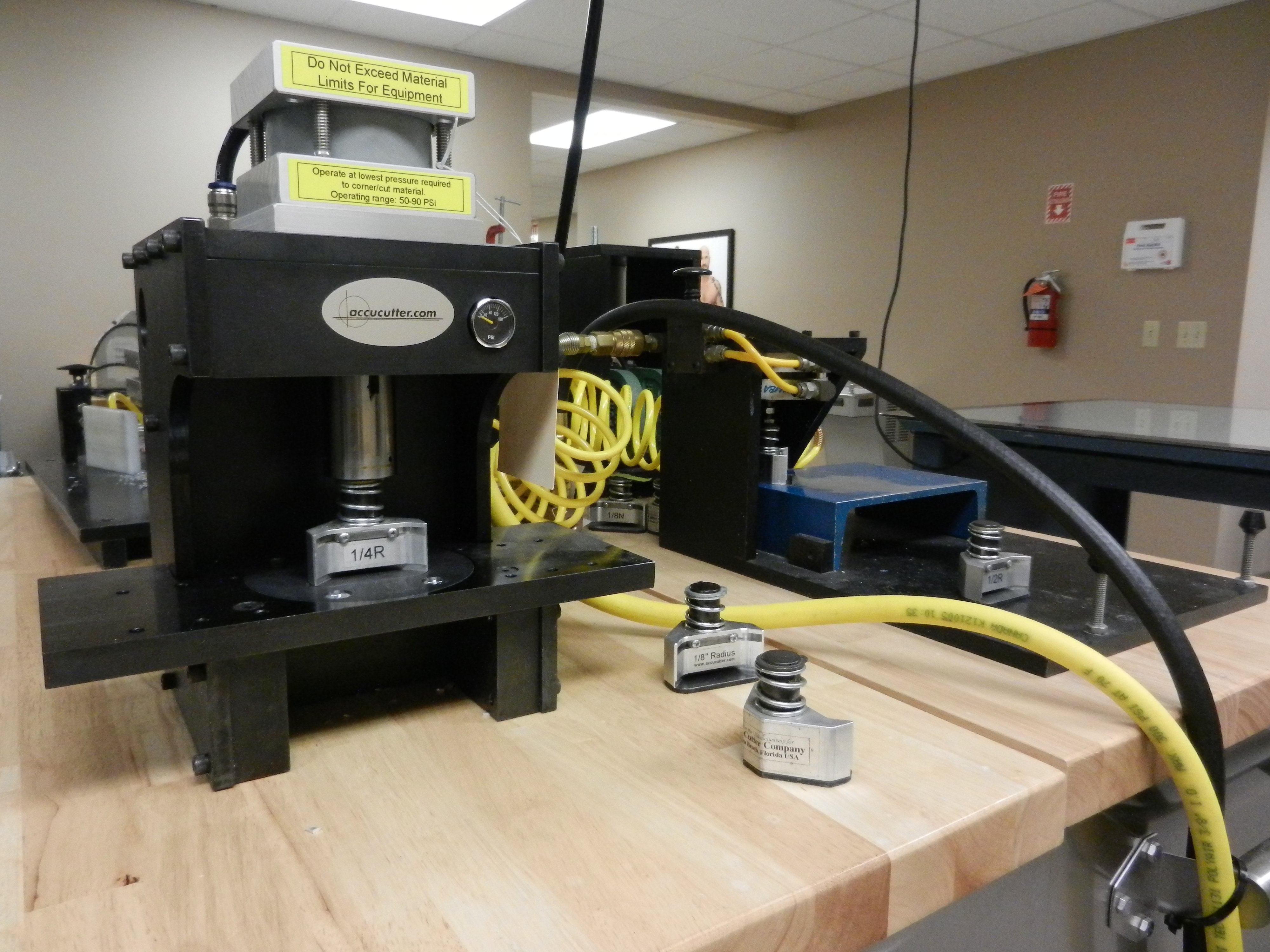

The PEC Metalphoto workshop features an open area where the nippers and hole punchers, once down the hall in the plaque-fabricating area, are installed on mobile tables. Both a new radius-corner nipper and a new shearer for cutting the metal have joined the existing equipment. One mobile table was fabricated in-house for some of this equipment, adding to the flexibility of the space.

“We worked with Medalist Manufacturing in Pella to custom build our hole punchers to run on pneumatic power,” added Cory. More shelving was also incorporated.

The combination of new equipment and a more streamlined workspace significantly increased the capacity Pella Engraving Company can offer its Metalphoto customer base. PEC is now more capable than ever of using its Metalphoto process to create high-quality, durable, and economic plaques, awards, serial tags, and more.

If you’ve got questions about a job and wonder if Metalphoto is a good option for you, contact us today!