Metalphoto is designed to withstand corrosion, abrasion, exposure to chemicals, and many other harsh environmental conditions.

When it debuted in 1950, the Metalphoto® process revolutionized the label, plaque, sign, serial and ID tag, and nameplate-making industry. Once the technology was made public in 1958, it became an indispensable capability for companies around the world, including Pella Engraving.

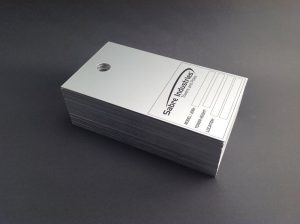

Metalphoto is a specialized type of photosensitive anodized aluminum designed to stand up to hard use and harsh environmental conditions. The secret of its durability? After the aluminum is anodized, text and images are actually sealed inside the metal. Both steps ensure protection against corrosion, sunlight, temperature changes, abrasion, salt spray, and exposure to chemicals. One frequent PEC Metalphoto customer reported attempting to scratch their serial ID tags with a key to no avail. These steps also guarantee the plaque, nameplate, sign, label, or tag will remain smooth, crisp, and legible for years to come.

Because words and images are actually sealed inside the aluminum, Metalphoto plaques and tags will remain crisp and legible for years to come.

This amazing durability, combined with high-resolution photo and data embedding capabilities, make Metalphoto the product of choice for many manufacturers and military and government organizations, including:

- U.S. Department of Defense

- NASA

- U.S. Navy

- U.S. Army

- Boeing

Pella Engraving was an early investor in Metalphoto equipment. Previous PEC Co-Owner John Vroom had the foresight to encourage his son and current Co-Owner, Jeff, to integrate the process into the company’s manufacturing capabilities. For more than 20 years, Pella Engraving has been proud to use the Metalphoto process to create highly durable ID tags, ID plates, and plaques to fit the needs of our customers.

Check out our ID and serial tag and Metalphoto plaque services to learn more about how PEC uses anodized aluminum.